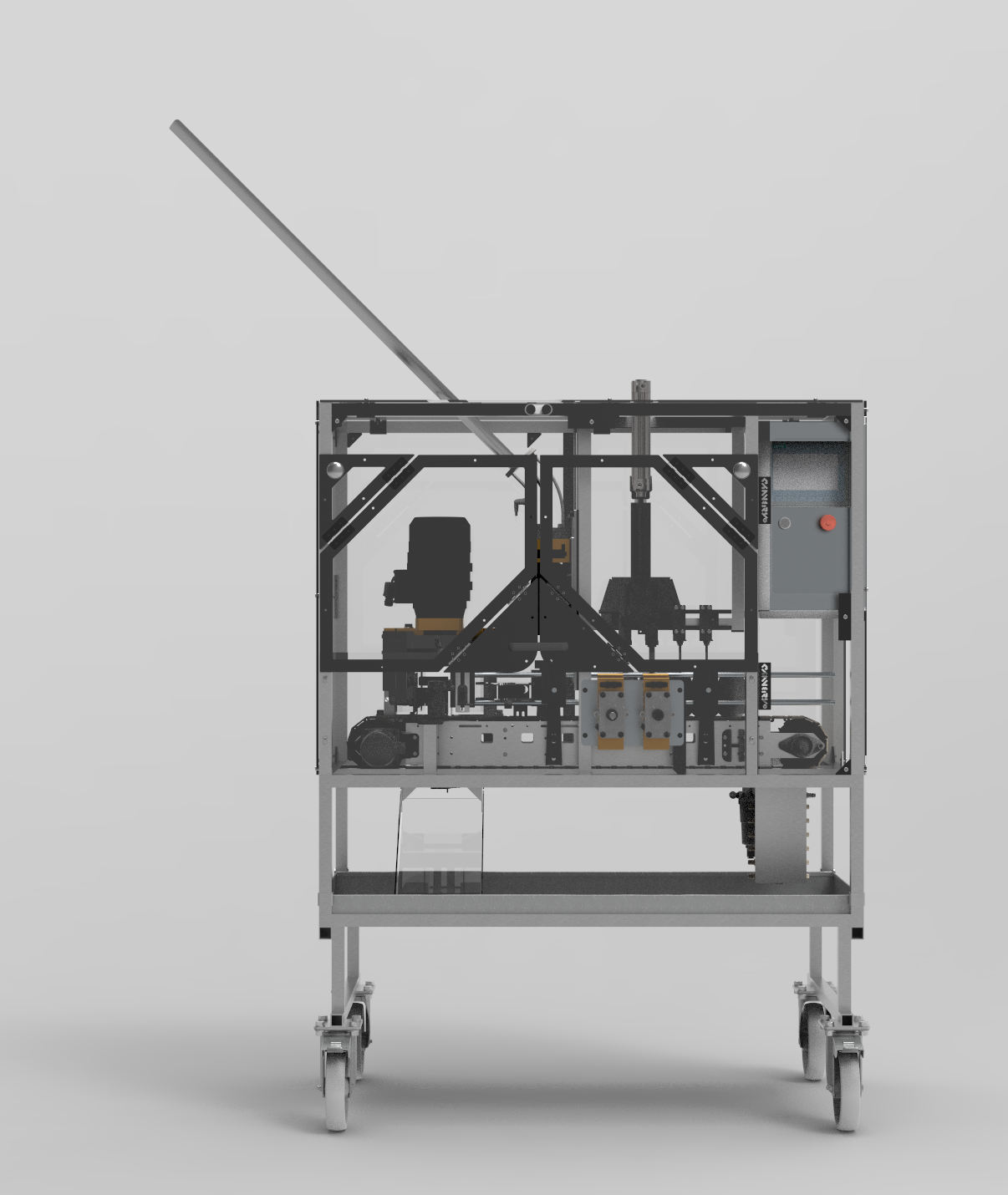

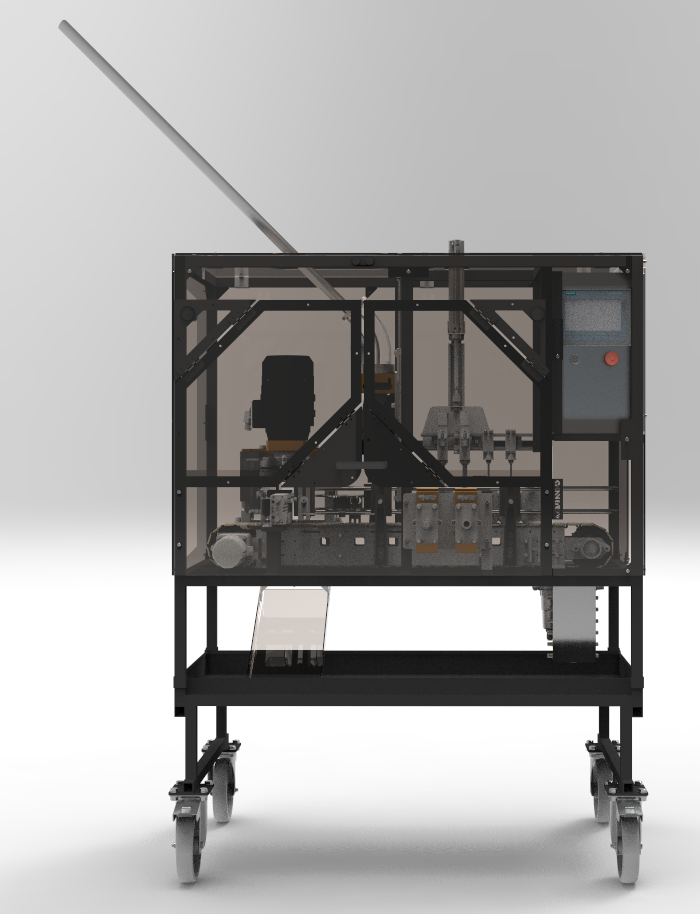

It’s not a flagship — it’s a rescue boat, built to ride the wave of the canned drinks movement.

No need to wonder what if, maybe, could it, or would it. Cannery Compact is your hands-on partner for entering the beautiful world of canned beverages.

Dive into the brilliance of the fully equipped, top-level Cannery Compact.

With its extraordinary painted frames, bronze-toned glasses, and origami-style doors, this model is designed to make a lasting impression. Our engineering team meticulously crafted every detail to ensure it’s something you’ll always remember.

And we’re with you every step of the way.

Our Cannery-Care after-sales service delivers VPN-enabled remote access for our support team, ensuring fast and efficient assistance when you need it most. Every question gets a quick, helpful response — so you can keep canning with confidence.

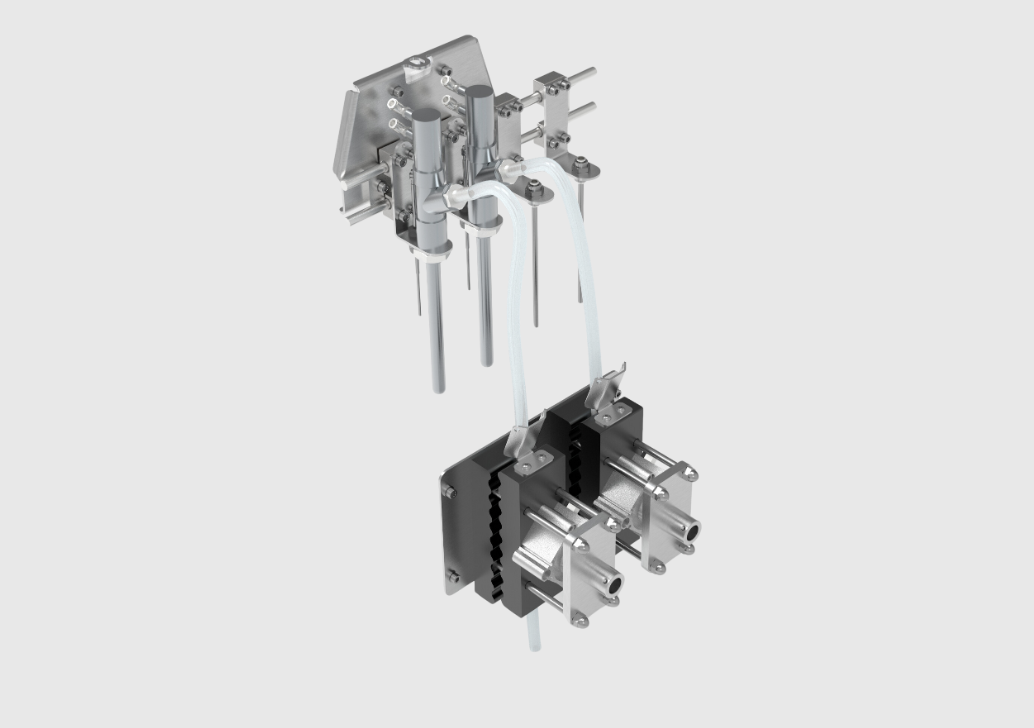

Counter Pressure Fillers are engineered for beverage producers who demand the highest quality and consistency. This technology allows precise filling of highly carbonated drinks—such as sparkling water, craft sodas, kombucha, energy drinks, and beer—by equalizing pressure inside the can during filling. The result is reduced foaming, minimal CO₂ loss, and an extended shelf life, ensuring premium product quality in every can.

Where engineering meets elegance and efficiency.

These space-saving, precision-engineered doors aren’t just practical—they’re unforgettable. They grab attention, spark curiosity, and leave visitors impressed. More than just a functional feature, Origami Doors reflect your out-of-the-box thinking. They make your brewery a true symbol of innovation and creativity.

With the FUNK Edition, your machine becomes the centerpiece of your brewery — a bold, colorful masterpiece that breaks all the rules of “standard.”

We’ll take that gray stainless steel frame and transform it with high-durability powder-coated paint in any color you can imagine.

Think IPA Golden, Yeast White, or Foamy Transparent — okay, maybe not that one, but you get the point. Want something loud like Lamborghini Green? Mysterious like Midnight Black? Or maybe you’ve got a wild idea we haven’t thought of yet?

Go FUNK and let your equipment reflect your creativity, your vibe, and your never-ending pursuit of awesome.

Not everything needs to be loud to make a statement.

Sometimes, true confidence comes from staying pure, raw, and unpolished — just like the classic stainless steel frame.

No extra colors, no flashy coatings — just the solid, industrial elegance that defines durability and reliability.

Stainless steel isn’t just a choice; it’s a legacy. It withstands time, work, and wear, aging with character while keeping its clean, professional look.

Because in the end, classics never go out of style.

Pros:

Simple Operation: Straightforward design makes it easy to use.

Versatile Applications: Suitable for a wide range of can types and beverage styles.

Consistent Fill Levels: Delivers reliable and accurate filling every time.

Hygienic Design: Easy to clean and maintain for optimal sanitation.

Durable Construction: Built to last with robust materials.

Fast Process: Two-step filling with continuous flow ensures efficiency.

Cons:

Limited CO₂ Retention: Less effective at preserving carbonation, making it less suitable for highly carbonated beverages.

Potential for More Foam: Increased foam formation may occur, requiring additional manual adjustments during filling.

Summary

Atmospheric fillers are a great choice for businesses seeking a cost-effective, simple, and versatile filling solution — particularly well-suited for small to medium-sized production runs and less carbonated beverages.

Pros:

Superior CO₂ Retention: Excellent for filling highly carbonated beverages with minimal carbonation loss.

Reduced Foam Formation: Less foaming during the filling process ensures more consistent product quality.

Advanced Technology: Offers sophisticated controls for precise adjustments and optimization.

Versatile Applications: Ideal for a wide range of beverage types, especially those requiring high carbonation levels.

Cons:

Higher Cost: More expensive to purchase and maintain than atmospheric fillers.

Complex Operation: Requires skilled operators and deeper technical understanding.

Maintenance Intensive: Advanced components demand more frequent upkeep.

Longer Setup Time: Takes more time to configure and switch between can sizes.

Summary

Counter pressure fillers are ideal for companies that need to maintain high carbonation levels and strict quality standards. They are especially well-suited for premium products — though they come with higher costs and added complexity.

When ordering your Compact, you should decide which filling technology best matches your drinks and production style — Counter-Pressure for carbonated beverages, or Atmospheric for still and lightly sparkling products.

This choice is important because your machine will be carefully configured and set up at our factory according to the option you select. That way, once it arrives, it’s ready to plug in and start running without extra adjustments.

Lineup technical details

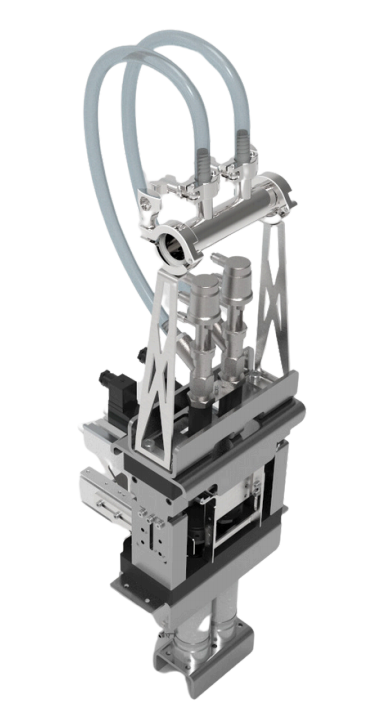

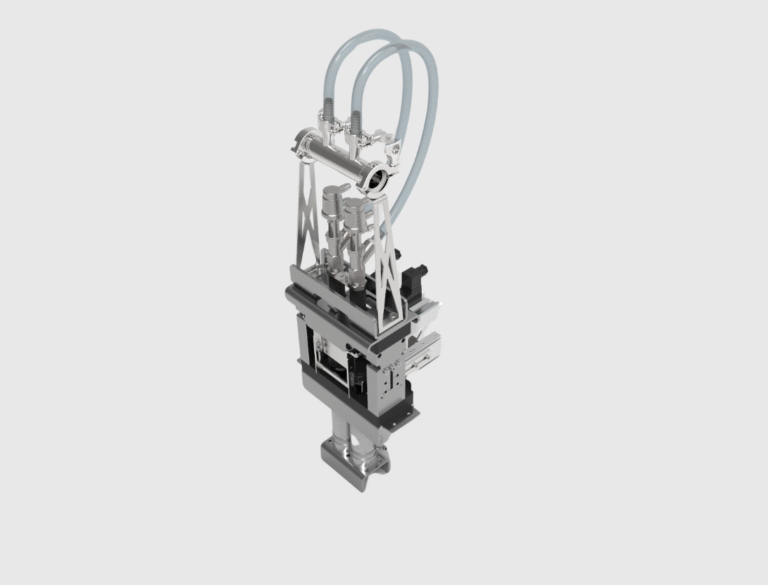

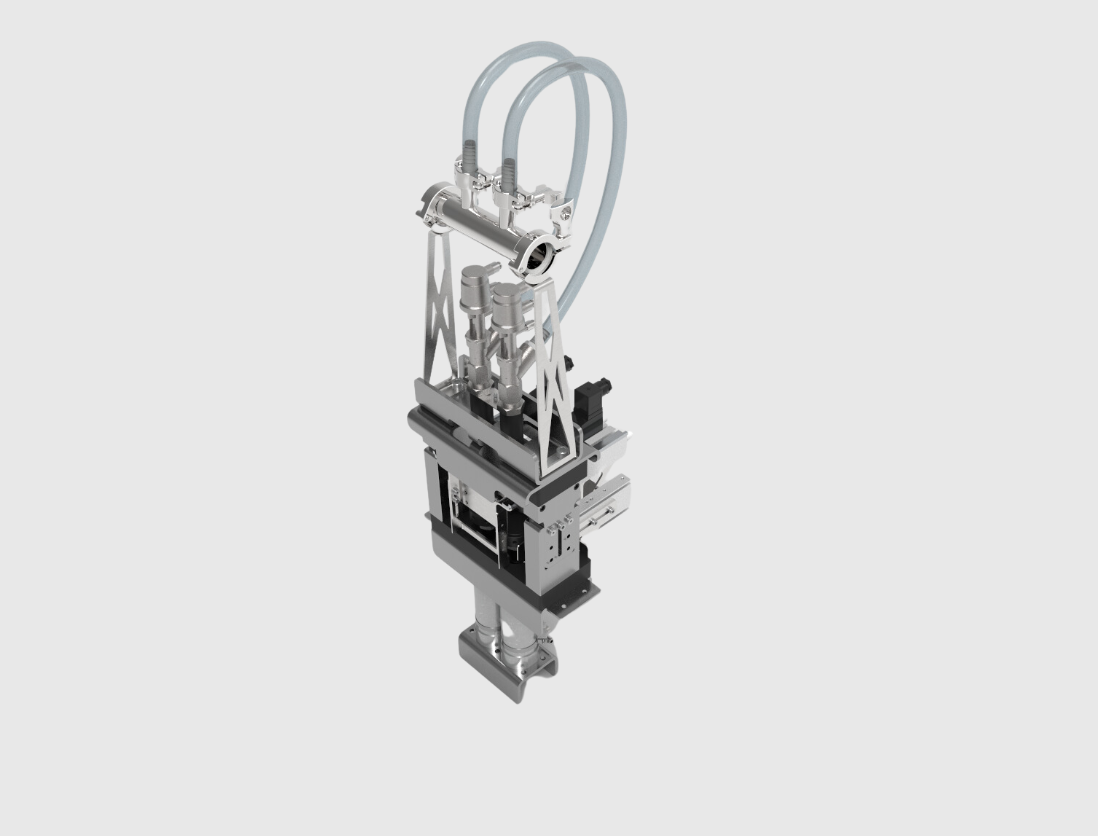

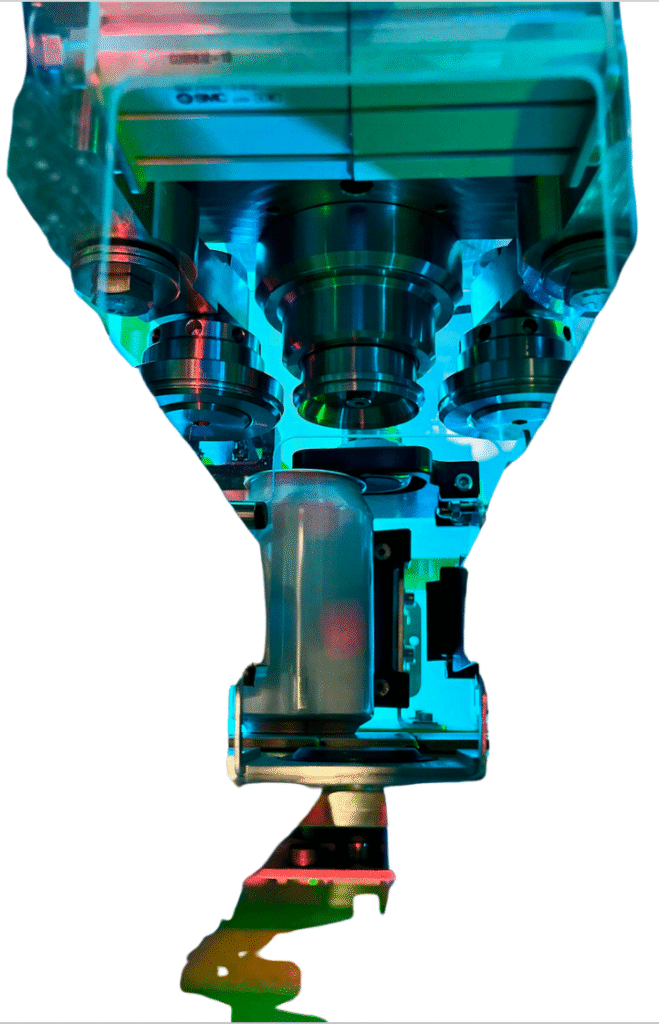

Designed from scratch to meet real brewery needs our seamer is the beating heart of your canning line. It’s smooth, durable, and easy to maintain. And let’s face it — it just looks awesome in action.

Because when it comes to canning, every detail matters — and we’ve absolutely nailed this one. Different can formats often bring new challenges to everyday canning. Thanks to our modular seamer design, format changes are fast, precise, and hassle-free — keeping your production flexible and efficient no matter the can size.

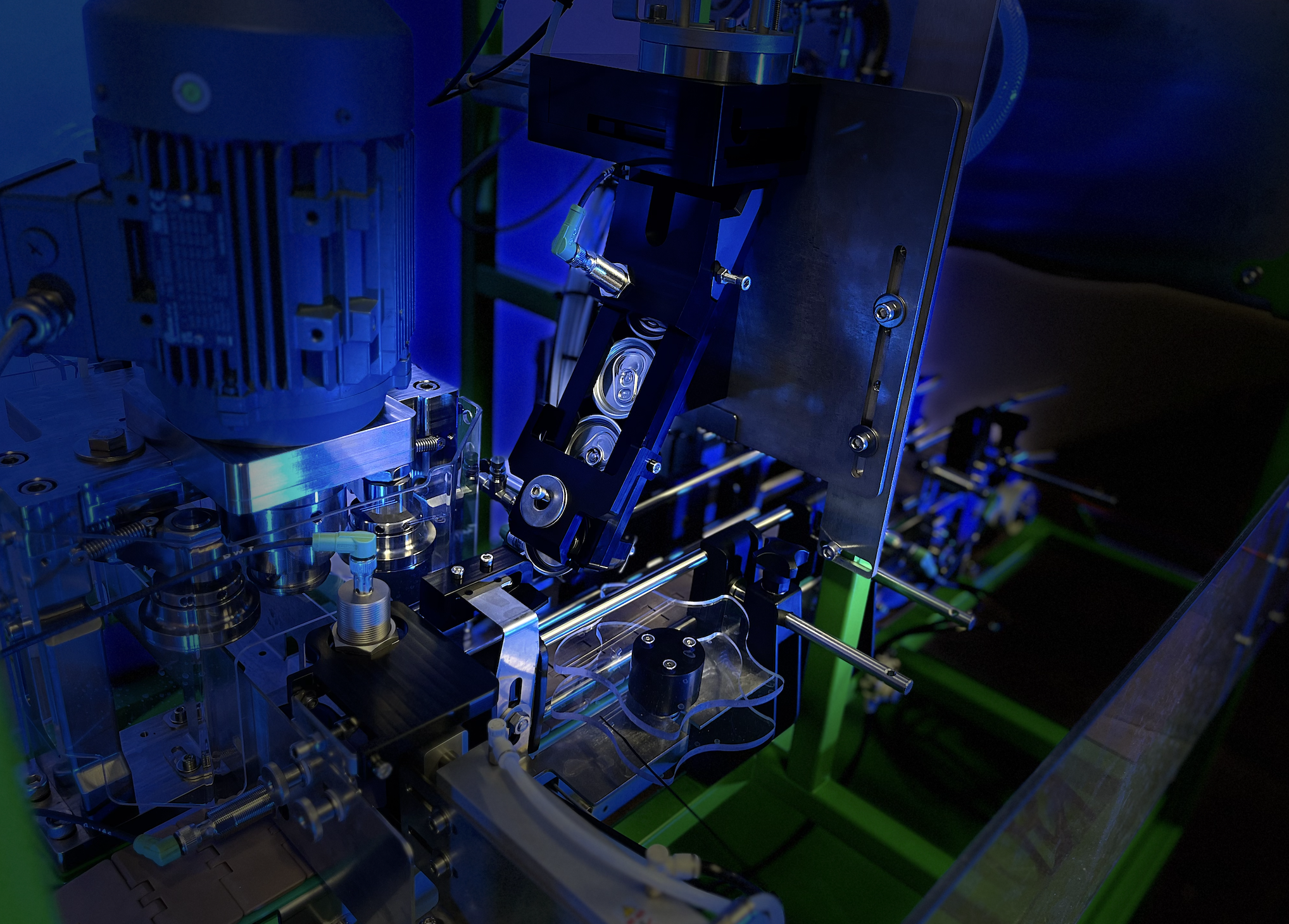

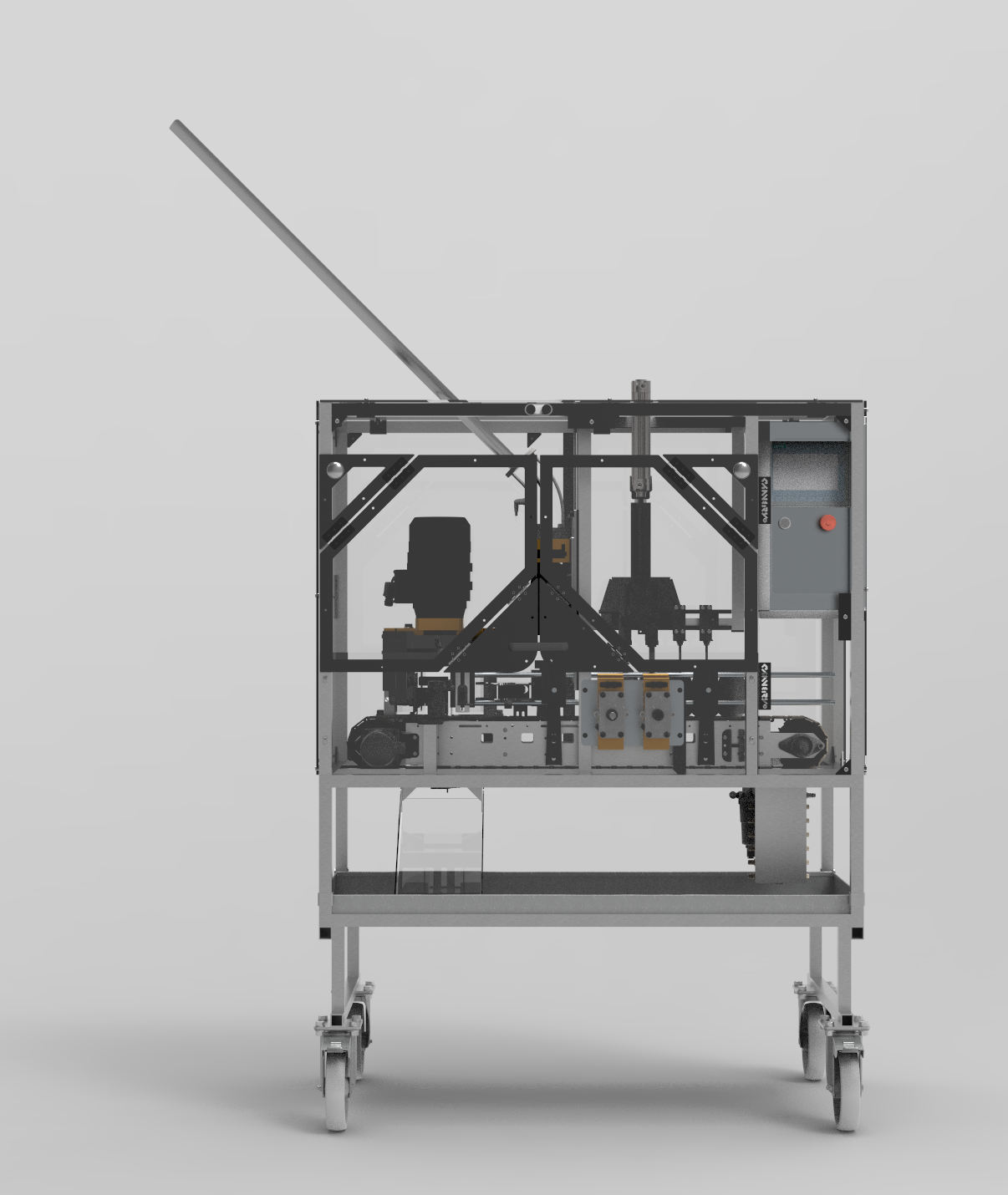

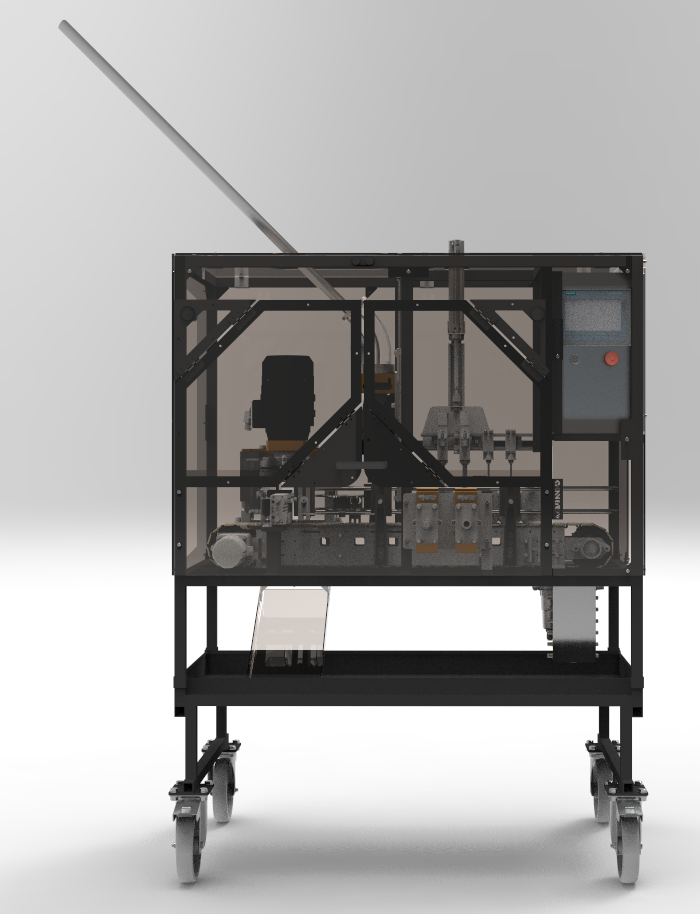

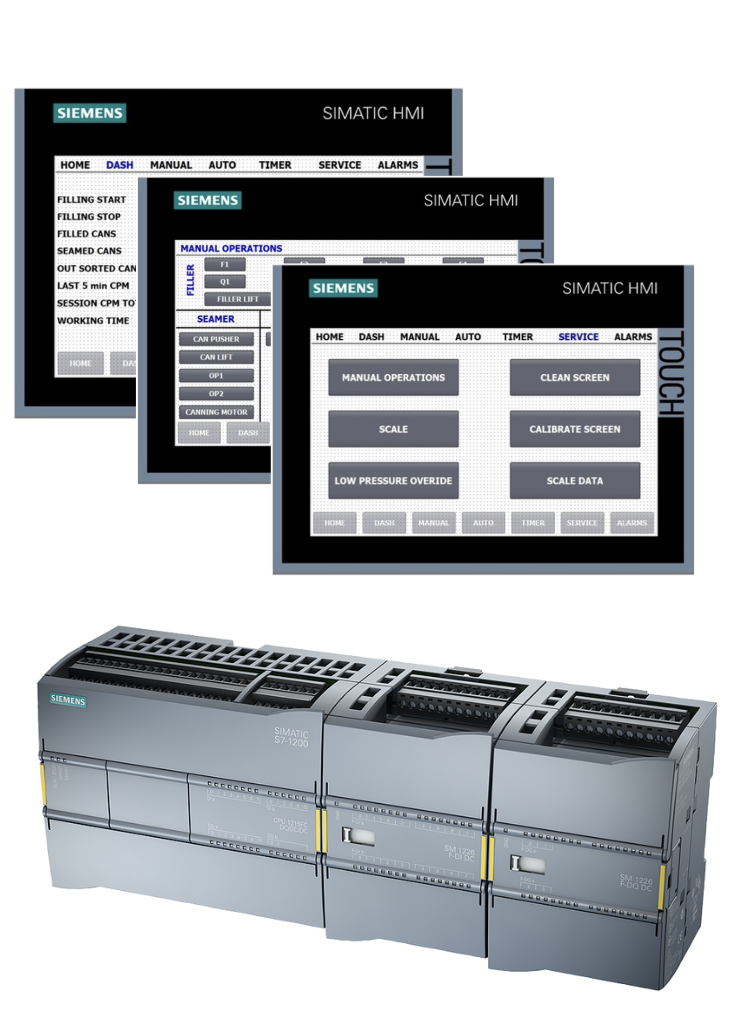

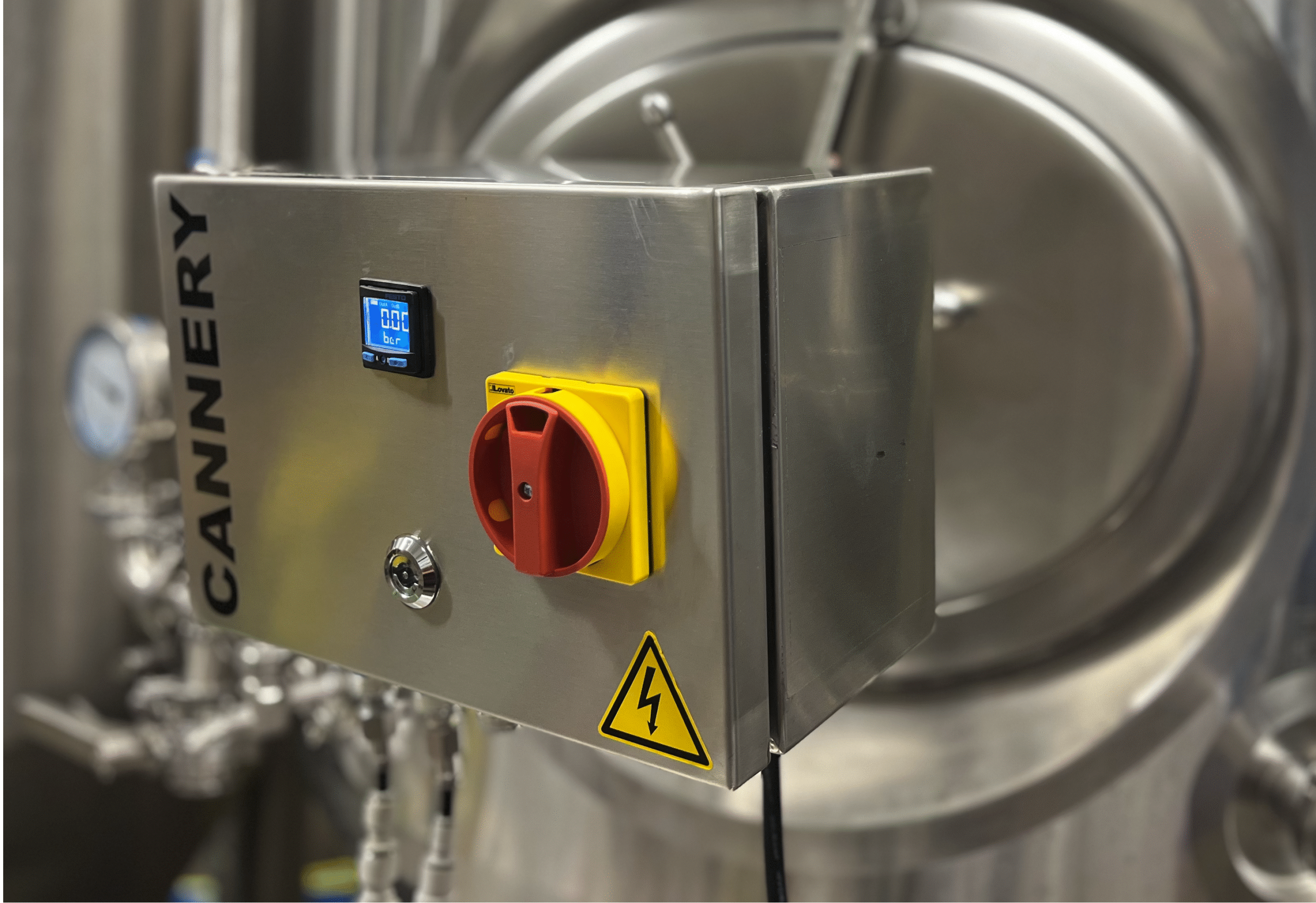

At the heart of the Cannery COMPACT is a commitment to cutting-edge automation and uncompromising engineering.

Collaborations with globally recognized component providers such as Siemens, Phoenix Contact, Omron, Festo, SMC, and others ensure that every part of the machine is engineered for maximum durability, reliability, and safety.

Designed entirely around the metric system, the Cannery COMPACT simplifies the after-sales process. There’s no need to deal with inch-based measurements, allowing focus to remain on what truly matters in drink production.

Whale Tail

The Whale Tail is our clever solution for smooth can feeding into your canning line. Inspired by nature and designed for simplicity, it uses gravity to guide cans gently and reliably into position. It’s easy to install or remove, holds up to 200 cans depending on format, and weighs just 29 kg. A perfect mix of simplicity and smart engineering, ensuring your production keeps flowing.

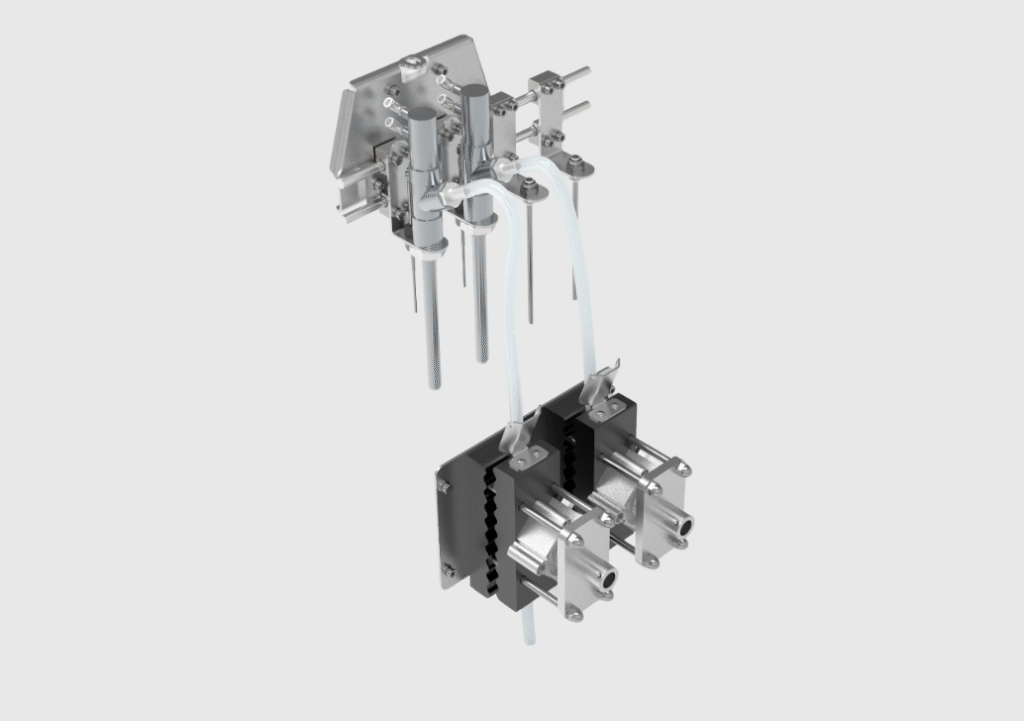

Labeller

A reliable labeling machine for small and medium-sized companies that aim to produce faster and reduce the budget for purchasing the labeler by 10-40% compared to the competition. This is a robust and user-friendly machine with modern aesthetics and an intuitive controller.

Production capacity L100 with wrap-around label:

– up to 3,000 (100 ml) cans or bottles per hour,

– up to 2,600 (0.5 L) cans or bottles per hour,

– up to 1,800 (0.75 L) bottles per hour.

IMPULSE

An advanced CO₂ doser designed to maintain constant head pressure in the brite tank. Ensuring a smooth and controlled canning process. By preventing unwanted fluctuations, it guarantees consistent carbonation and minimizes unexpected beer behavior during canning.

Manual Depalletizer

A reliable and cost-effective solution for transferring cans from pallets to the production line. Designed for smaller production volumes or facilities seeking flexible operation, this manual depalletizer offers excellent control while maintaining operator safety and efficiency.

Available in different pallet formats, it allows for easy adaptation to various packaging standards. The process is simple: the pallet is lifted using a regular pallet stacker, and each layer of cans is manually removed by the operator. The horizontal table tilts downward, allowing cans to descend by gravity onto the Whale Tail, which guides them seamlessly into the canning line.

The Cannery manual depalletizer makes transitioning from pallet storage to production smooth and efficient—keeping your operations running steadily without costly automation investments.

The footprint is designed to fit into small production environments. You need approximately 2.5 × 1.5 meters of floor space for operation, with room for loading cans and packaging after filling.

Yes. Cannery COMPACT is optimized for single-operator use. While an extra pair of hands helps during peak runs or loading/unloading, one trained person can handle the full workflow smoothly.

Our system uses CO₂ flushing under the lid and optionally in the can itself before seaming, helping reduce oxygen pickup and maintain shelf life and flavor stability for sensitive products like beer or kombucha.

Yes. We offer leasing and long-term rental options, especially useful for low budget production. Contact our team to get a tailored offer.

No special tricks is needed. We provide a startup training session, user manual, and optional remote onboarding video call. Within a few hours, your team will be confidently running the machine.

Cannery OÜ, Hoiu 16, Laagri, Estonia