Our counter-pressure technology was designed for soda makers who know that taste is everything. By preserving bold flavors and high carbonation, our system delivers a superior product — the kind that keeps customers coming back, again and again.

Want more sales?

Brands powered by Cannery’s counter-pressure machine aren’t just growing — they’re skyrocketing. When your drink tastes better, it sells better. That’s why new-age leading brands trust Cannery. Read more from our blog.

More fizz, more flavor, more fans.

A design that’s not just functional — it’s legendary.

Counter Pressure Fillers are engineered for beverage producers who demand the highest quality and consistency. This technology allows precise filling of highly carbonated drinks—such as sparkling water, craft sodas, kombucha, energy drinks, and beer—by equalizing pressure inside the can during filling. The result is reduced foaming, minimal CO₂ loss, and an extended shelf life, ensuring premium product quality in every can.

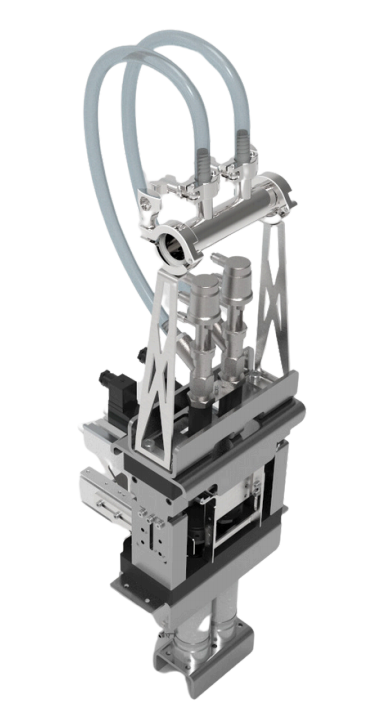

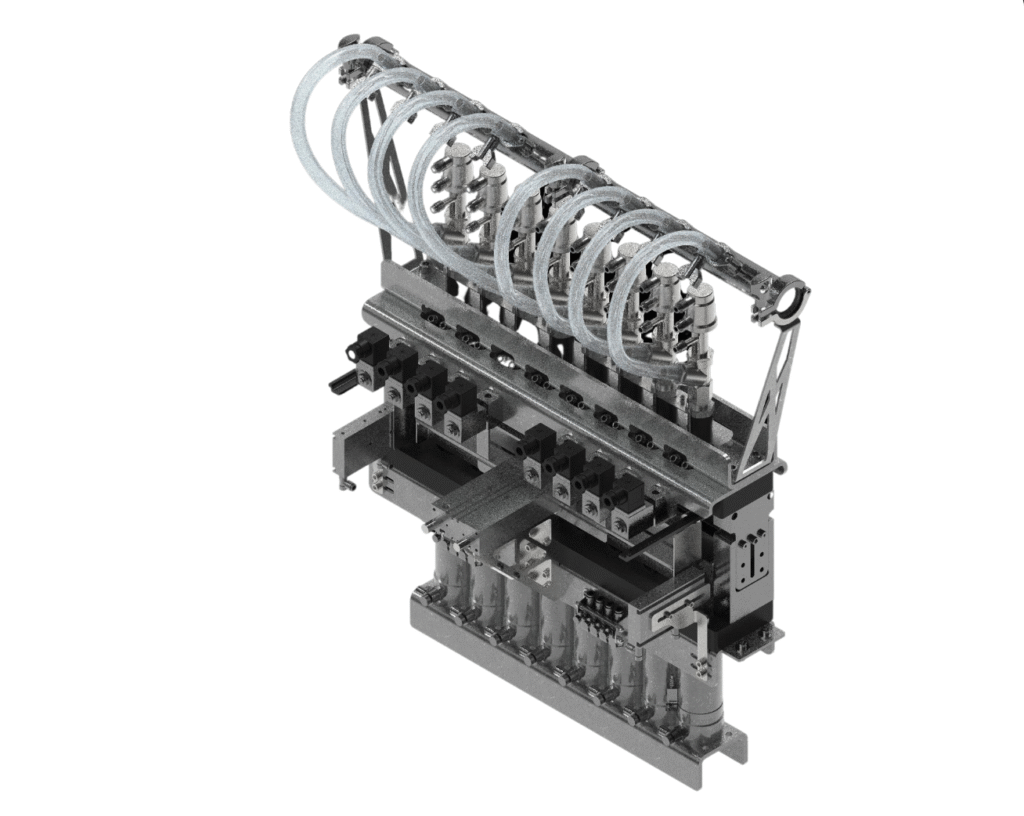

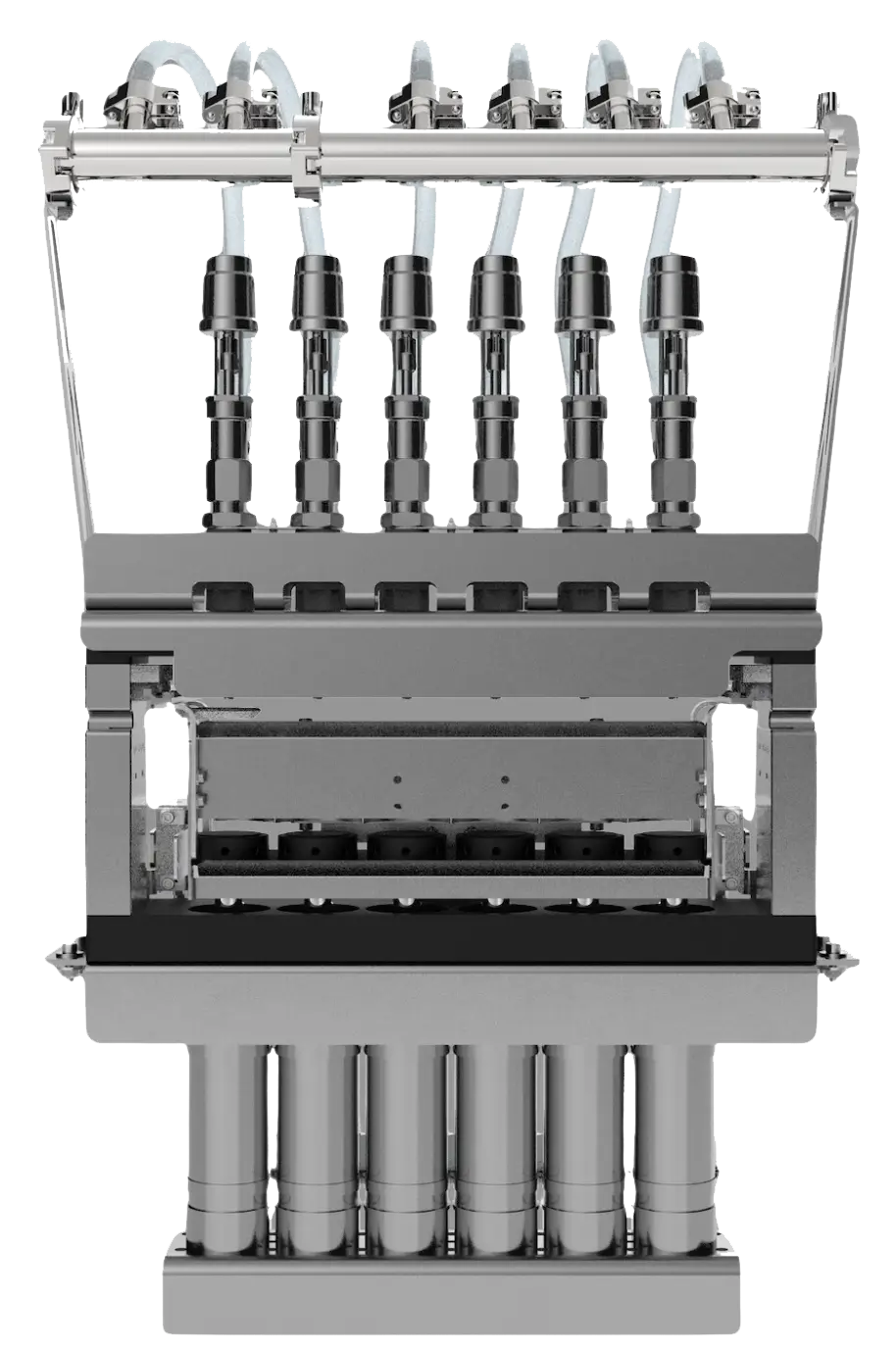

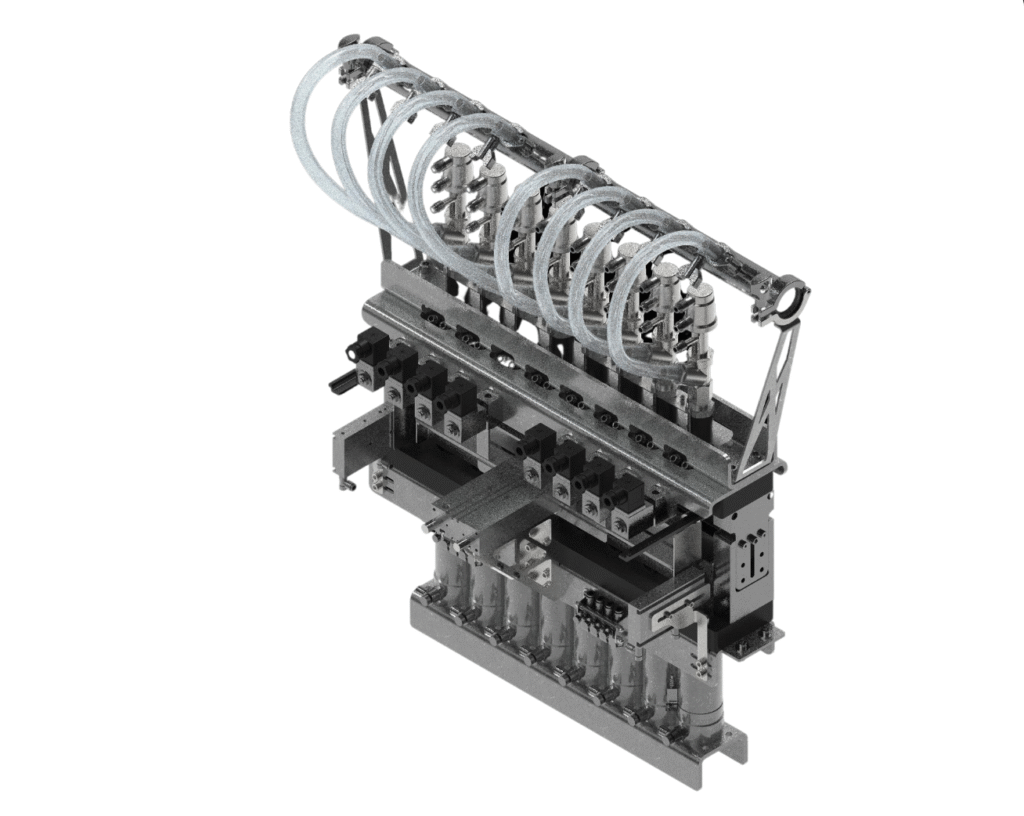

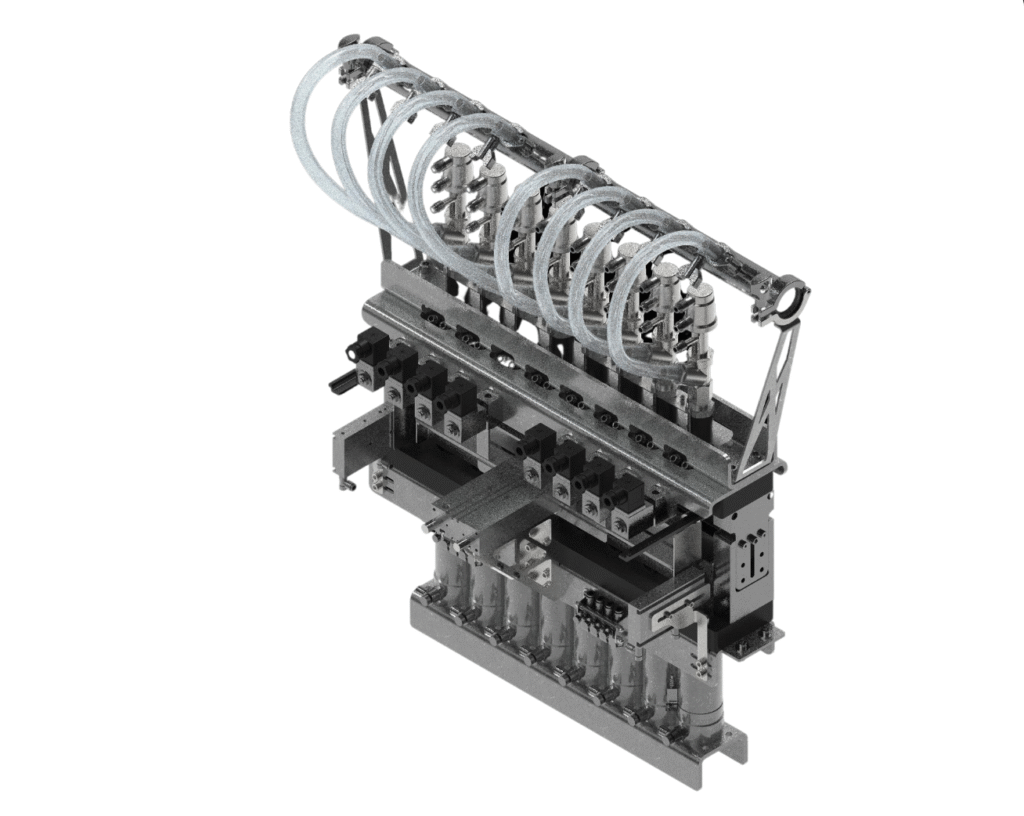

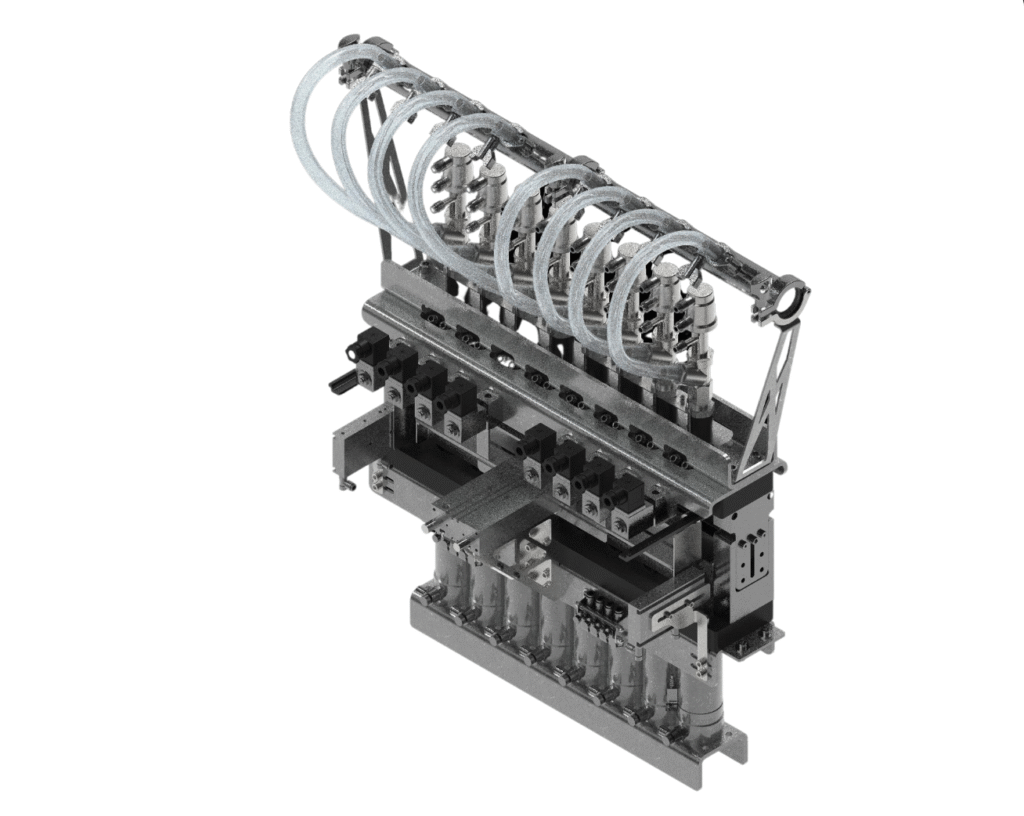

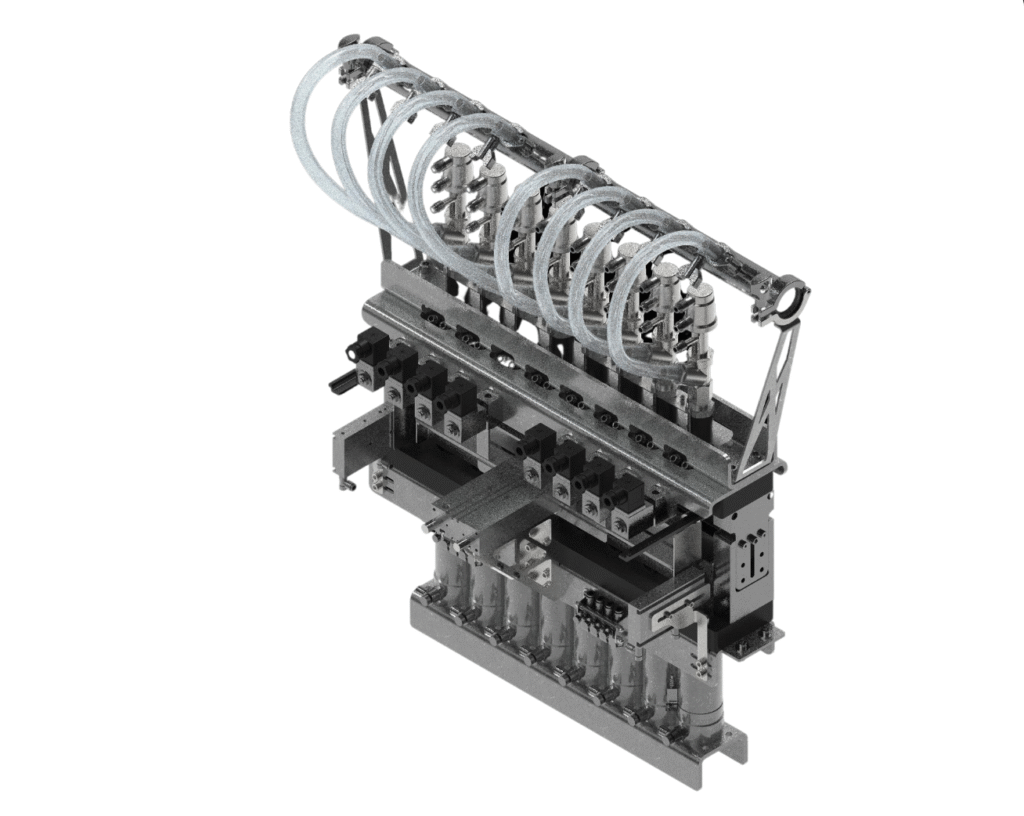

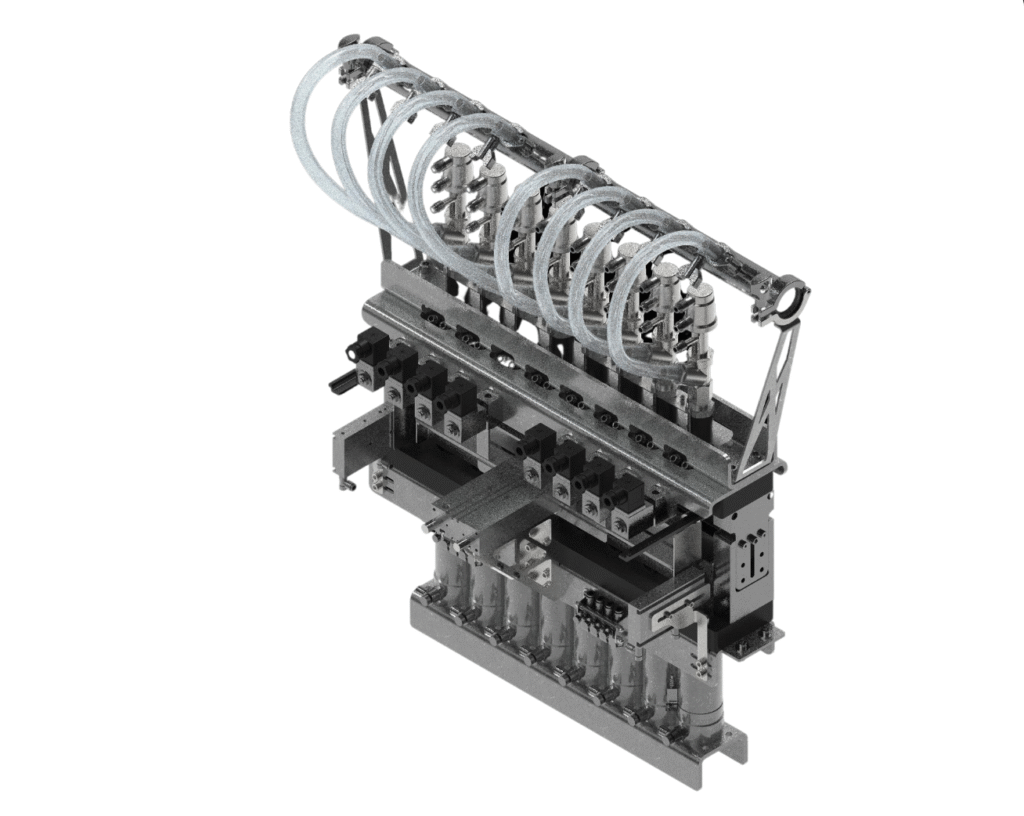

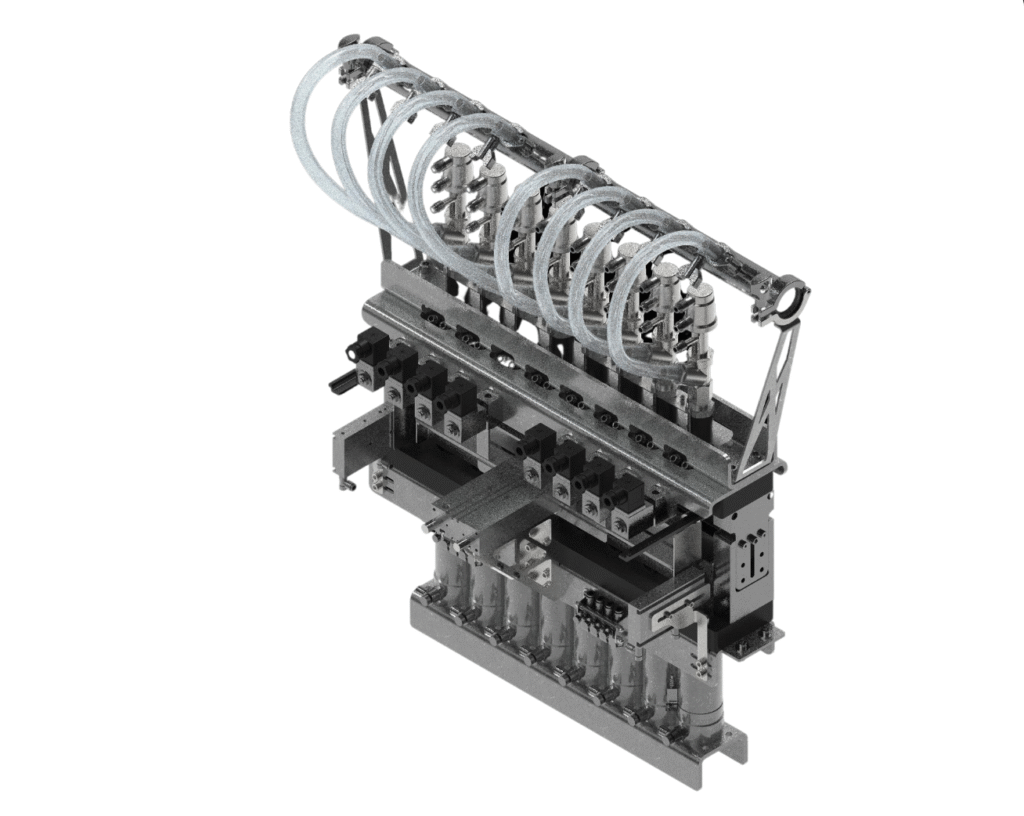

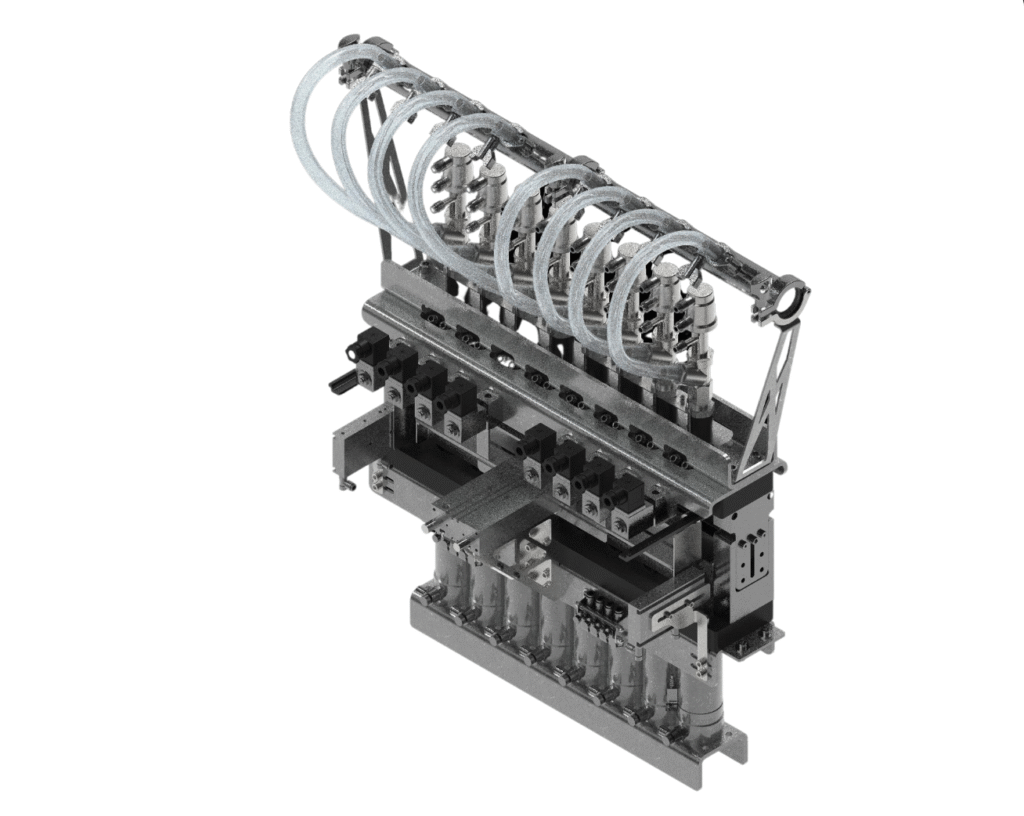

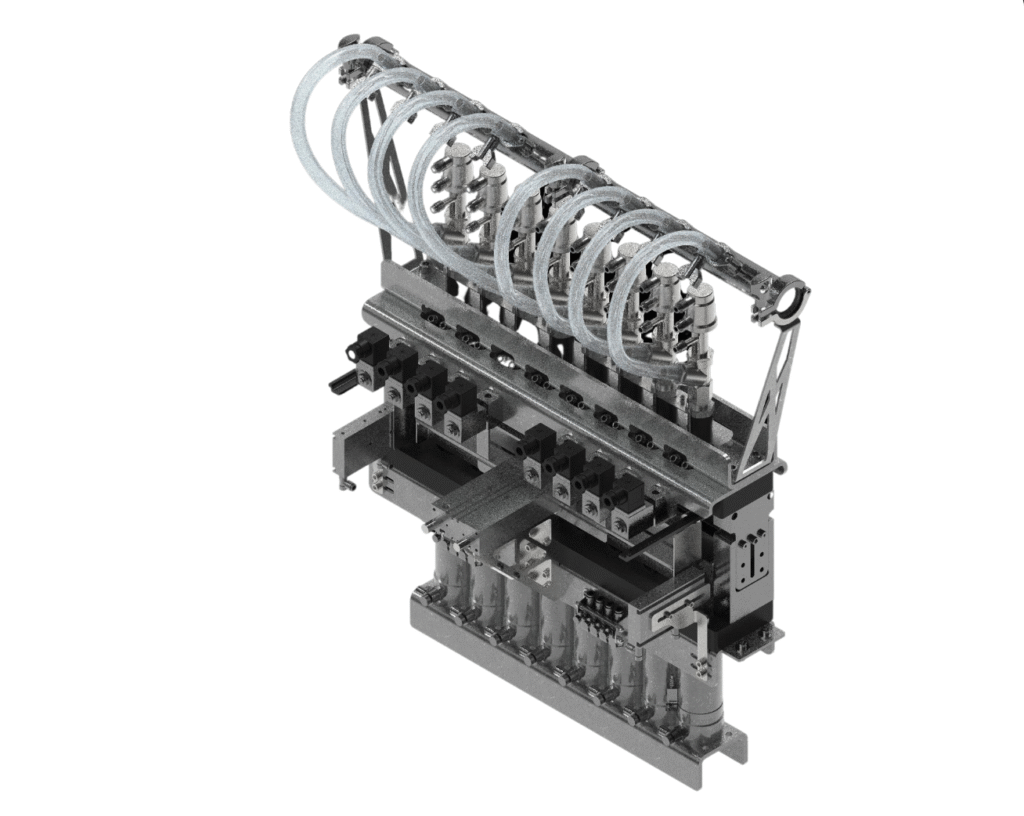

Smooth deployment. Cannery Counter isobaric / counter pressure filler cassette is available in a rack mount design — with all the same performance features and configuration for every can. Every single filling cassette carries all major features for necessary performance. Quick adaptors simplify the change between filling cassettes.

Stainless steel handles the strength, and plastic gently treats the cans during the entire process.

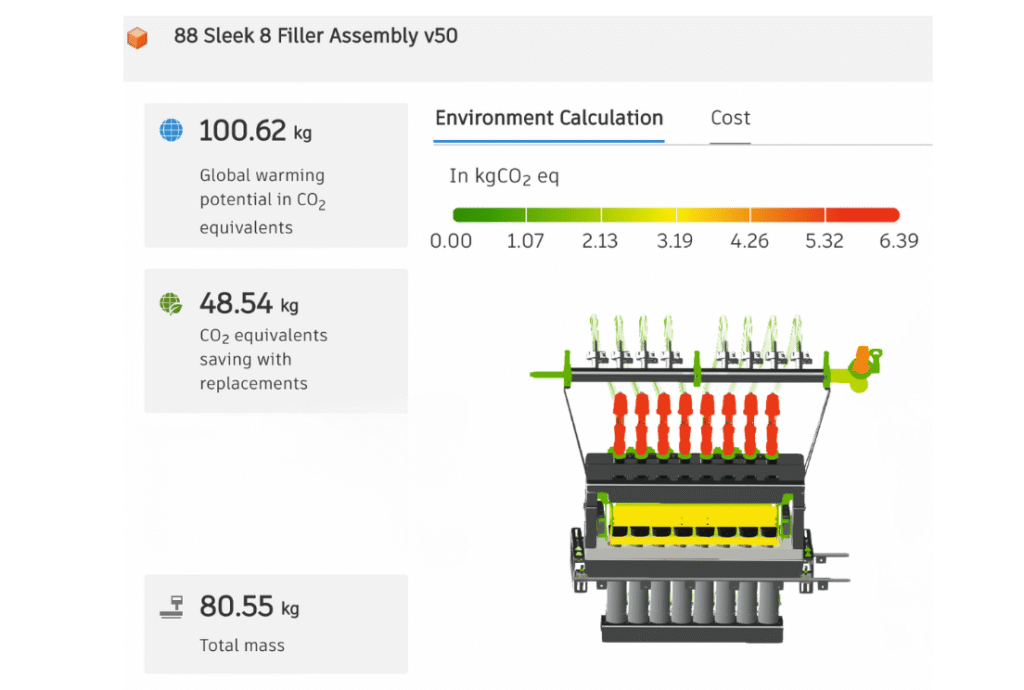

Each cassette is built to handle the demands of modern beverage production—whether it’s for sparkling water, kombucha, or low-calorie energy drinks—helping you meet consumer demand for healthier, eco-friendly choices. With quick-change adaptors, durable stainless steel components, and innovative flow control, the CANNERY filling cassette helps you keep up with demand while keeping your carbon footprint down.

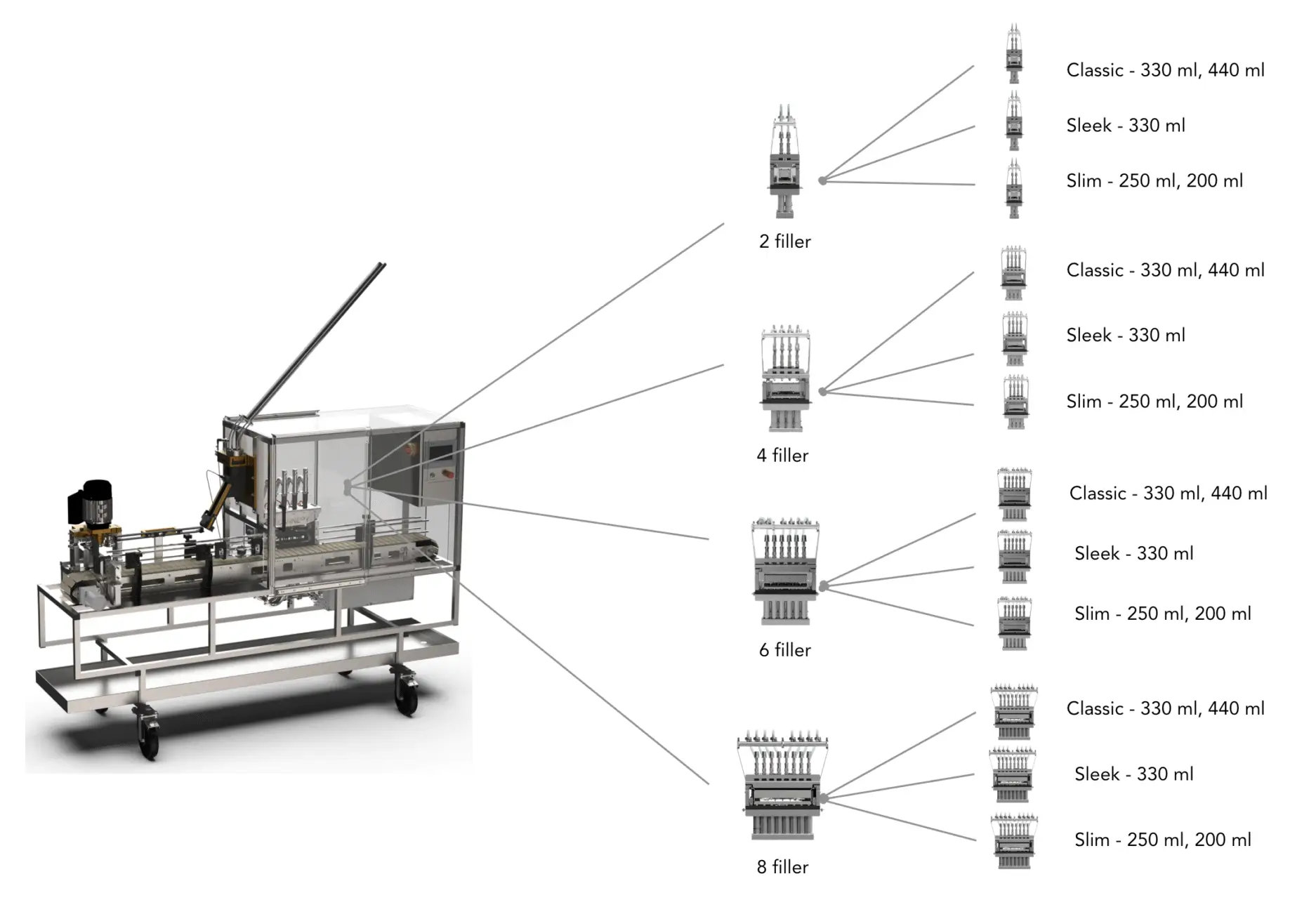

Our modular system lets you choose between different filler configurations and can sizes. Just swap the cassette — no need to change the whole machine.

When it comes to product design, there are always competing priorities. Important decisions for durability, strength, weight, materials, and cost can quite literally make or break a product. But there’s another factor that is quickly climbing to the top of the priority list: sustainability.

Building a stainless steel isobaric machine and claiming it's carbon neutral is no easy feat. However, we believe that everything we create should be designed with the environment in mind.

We've spent countless hours researching and testing materials to ensure that our machines not only function at the highest level, but also have the lowest environmental impact possible.

Sending all our production leftover materials to recycling. Like used cans, cables, packaging materials and other waste disposals

Reusing pallets or pallets material for machine packing. Overall we have reduced 80% of material used for machine shipping.

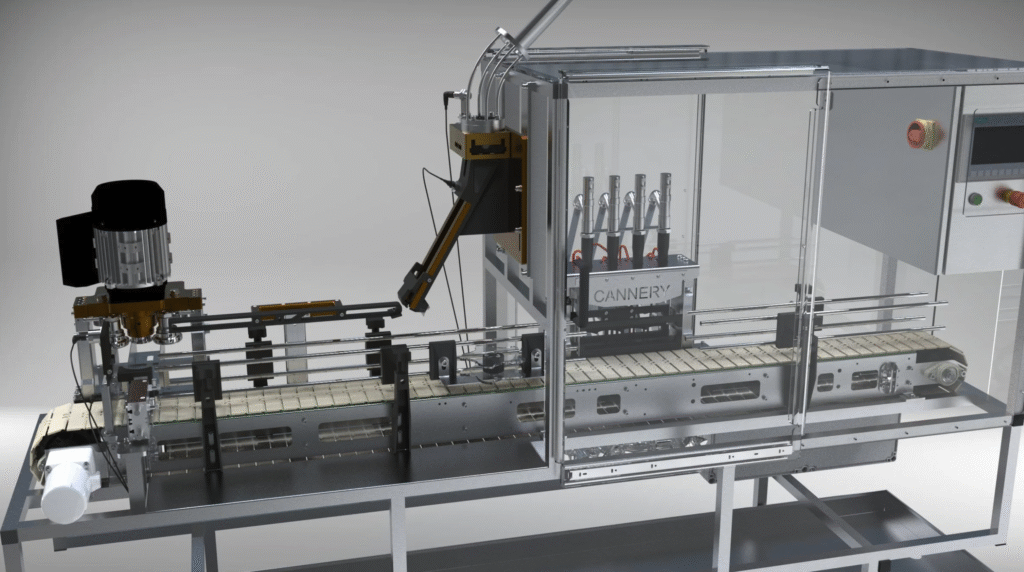

Cannery Counter isn’t just a frame for filling cassettes — it’s the complete engine of your canning line. It seamlessly hosts counter-pressure cassettes while integrating advanced controls, remote connectivity, lid dispensing, smart seaming, and rinsing.

It’s modularity redefined — and it’s worth seeing for yourself.

Our clean, Nordic design is more than a look—it’s a philosophy of simplicity woven into every detail of our engineering and every moment of your experience. It’s simplicity you can see, feel, and trust.

Designed from scratch to meet real brewery needs, our seamer is the beating heart of your canning line. It’s smooth, durable, and easy to maintain. And let’s face it — it just looks awesome in action. Because when it comes to canning, every detail matters — and we’ve absolutely nailed this one.

Different can formats often bring new challenges to everyday canning. Thanks to our modular seamer design, format changes are fast, precise, and hassle-free — keeping your production flexible and efficient, no matter the can size.

Our integrated lid cutter and dispenser is designed for precision and efficiency in modern canning lines. It handles CDL202 and CDL200 lid formats, cutting each lid cleanly from the pack and feeding them one by one to the waiting cans with perfect alignment and speed.

Beneath the lid feed, a CO₂ dosing system enriches the space between the lids and cans with a CO₂-rich environment. This crucial step helps minimize dissolved oxygen (DO) levels during beer filling, preserving flavor, freshness, and product shelf life.

Together, the precise lid handling and CO₂ protection ensure every can is sealed under optimal conditions—delivering superior quality and taste in every pour.

At the heart of the Cannery Counter is a commitment to cutting-edge automation and uncompromising engineering.

Collaborations with globally recognized component providers such as Siemens, Phoenix Contact, Omron, Festo, SMC, and others ensure that every part of the machine is engineered for maximum durability, reliability, and safety.

Designed entirely around the metric system, the Cannery Counter simplifies the after-sales process. There’s no need to deal with inch-based measurements, allowing focus to remain on what truly matters in drink production.

Whale Tail

The Whale Tail is our clever solution for smooth can feeding into your canning line. Inspired by nature and designed for simplicity, it uses gravity to guide cans gently and reliably into position. It’s easy to install or remove, holds up to 200 cans depending on format, and weighs just 29 kg. A perfect mix of simplicity and smart engineering, ensuring your production keeps flowing.

Labeller

A reliable labeling machine for small and medium-sized companies that aim to produce faster and reduce the budget for purchasing the labeler by 10-40% compared to the competition. This is a robust and user-friendly machine with modern aesthetics and an intuitive controller.

Production capacity L100 with wrap-around label:

– up to 3,000 (100 ml) cans or bottles per hour,

– up to 2,600 (0.5 L) cans or bottles per hour,

– up to 1,800 (0.75 L) bottles per hour.

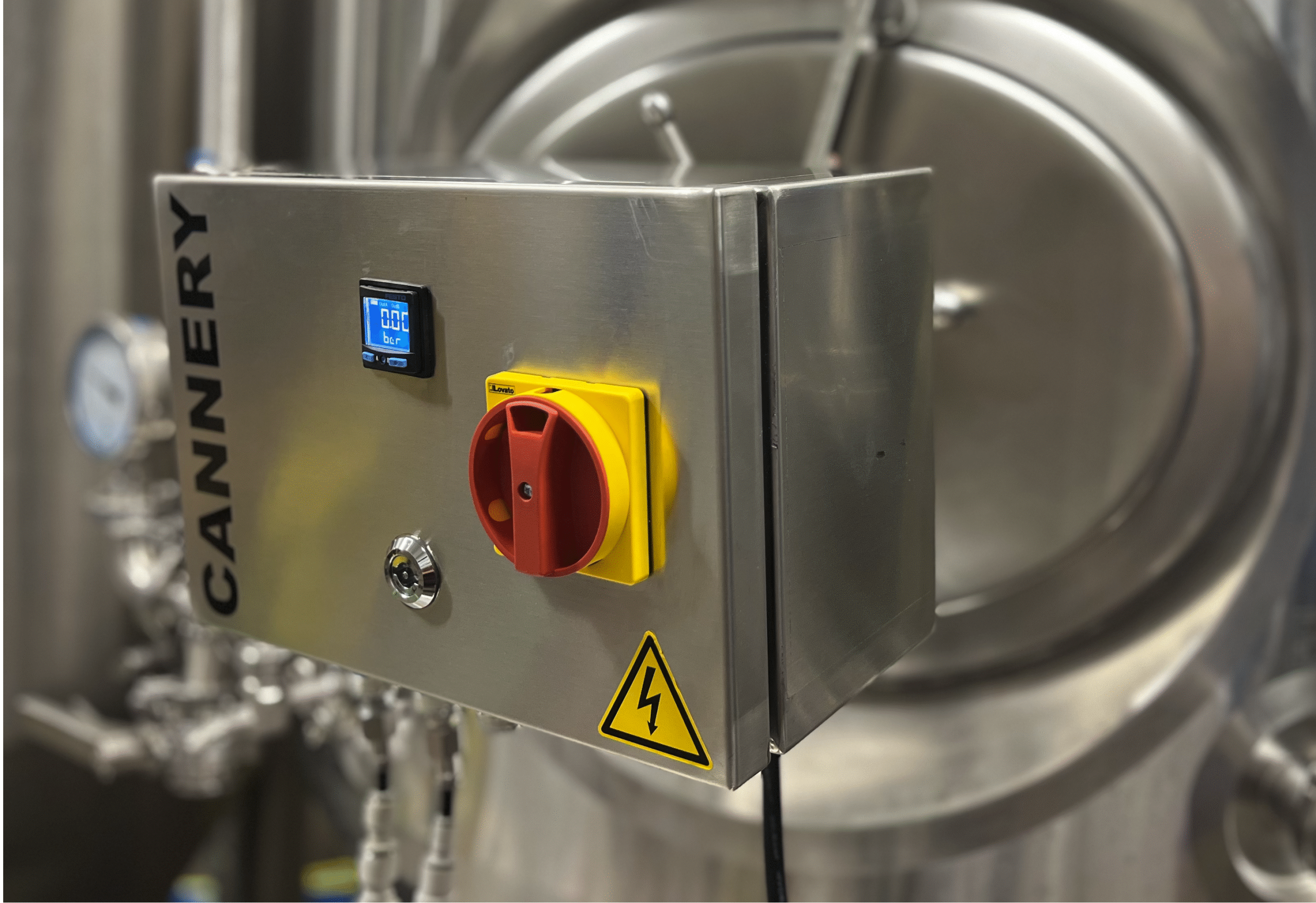

IMPULSE

An advanced CO₂ doser designed to maintain constant head pressure in the brite tank. Ensuring a smooth and controlled canning process. By preventing unwanted fluctuations, it guarantees consistent carbonation and minimizes unexpected beer behavior during canning.

Manual Depalletizer

A reliable and cost-effective solution for transferring cans from pallets to the production line. Designed for smaller production volumes or facilities seeking flexible operation, this manual depalletizer offers excellent control while maintaining operator safety and efficiency.

Available in different pallet formats, it allows for easy adaptation to various packaging standards. The process is simple: the pallet is lifted using a regular pallet stacker, and each layer of cans is manually removed by the operator. The horizontal table tilts downward, allowing cans to descend by gravity onto the Whale Tail, which guides them seamlessly into the canning line.

The Cannery manual depalletizer makes transitioning from pallet storage to production smooth and efficient—keeping your operations running steadily without costly automation investments.

Counter-pressure filling is essential for carbonated drinks like beer, especially for highly carbonated (above 3 vol/CO2) kombucha, lemonade, RTD or sparkling water. It helps retain CO₂ and reduce oxygen pickup, which improves shelf life, flavor, and product stability — especially critical for export or premium beverages.

Flexibility. You’re not buying a fixed-size machine — you’re investing in a platform. You can start small and scale as needed. The modularity, short changeover time, and open integration design give you long-term value. Think about it as a 2-seater mini car that expands into an 8-seater family car. Isn’t that cool?

Yes. The COUNTER comes with secure VPN access, allowing Cannery technicians to log in remotely for diagnostics, updates, or training — no need to wait for a site visit.

Yes, the entire system is built on a mobile frame with lockable wheels, making it suitable for breweries or co-packers who need to reconfigure their layout or relocate seasonally.

Yes. That’s one of the main advantages of the COUNTER platform. You can start with 2 or 4 filling heads and upgrade to 6 or 8 as your production grows — no need to invest in a completely new machine.